GRP Product Groups

Discover our complete range of GRP products, developed for maximum durability and safety. From gratings and profiles to custom-made solutions – we provide the right solution for every application. FlexxCon stands for quality, innovation, and tailor-made service.

GRP Handrails

Our GRP handrail systems comply with NEN-EN-ISO 14122 and are suitable for use in corrosive environments. The system is low-maintenance, lightweight and easy to install.

GRP Staircase

Our GRP staircases comply with NEN-EN-ISO 14122 and are suitable for use in corrosive environments. They are low-maintenance, safe and available as custom-made solutions.

GRP Platform Frames

Our GRP platform frames comply with NEN-EN-ISO 14122 and are suitable for use in corrosive environments. They are low-maintenance, strong and available as custom-made solutions.

GRP (Caged) Ladders

Our GRP ladders and caged ladders comply with NEN-EN-ISO 14122 and are suitable for use in corrosive environments. They are low-maintenance, safe and available as custom-made…

What does the process look like?

No project is the same. That is why FlexxCon starts from your specific requirements to deliver a custom GRP solution, developed through a transparent process of design, production, and delivery.

1. Client request

Every project starts with a clear question or challenge. We define the application, environment, and requirements in detail.

2. Solution and advice

We actively think along and translate the client’s request into a practical GRP solution that fits real-world use.

3. Engineering

Our engineers develop the design technically, including drawings and calculations, ensuring the product meets all applicable requirements.

4. Production

The product is manufactured in our own workshop, with craftsmanship and attention to detail.

5. On-site installation

Installation is carried out by our trusted and experienced installation partners, with whom we work closely to ensure safe and correct assembly.

6. Delivery and evaluation

After delivery, the project is inspected and evaluated. This allows us to guarantee quality and continuously improve our solutions.

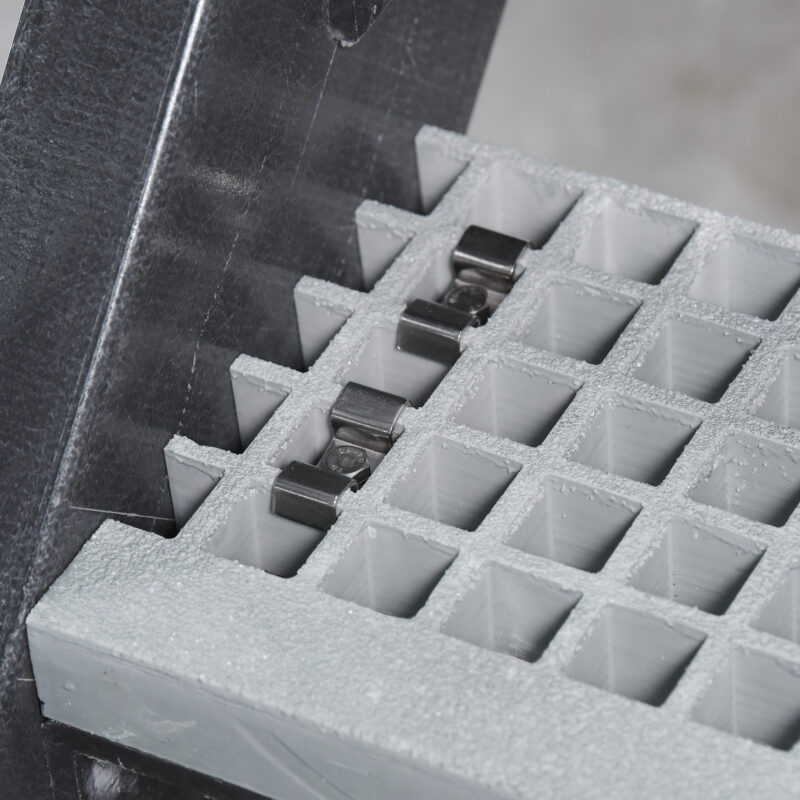

Everything about GFRP Structures

FlexxCon designs, engineers, and installs robust structures made of GRP (glass fibre reinforced plastic). Think of custom solutions such as platforms, staircases, maintenance platforms, walkways, gangways, escape routes, and stair towers. Our GRP structures add value in a wide range of applications.

Glass fibre reinforced plastic structures are corrosion-resistant and low-maintenance. GRP is therefore an excellent and strong structural material for use in corrosion-prone environments where water or (aggressive) chemicals are frequently present. Plastic structures are lightweight and easy to install. GRP structures are thus a strong alternative to steel structures and are also cost-effective.

Why choose GRP structures by FlexxCon?

- Corrosion-resistant

- Low-maintenance

- Lightweight

- Simple and cost-efficient installation: faster and more economical than steel

Impression of our structures

Frequently Asked Questions about GFRP structures

-

Standard GRP gratings from stock can be shipped immediately and are often delivered within 1–2 working days.

Customised GRP gratings are cut from stock panels. The exact delivery time depends on the desired dimensions and the current cutting schedule.

It is best to discuss the shortest lead time with you personally.Due to their complexity, GRP structures (such as stairs, landings and platforms) usually have a longer lead time.

However, we are flexible in planning and production and can, where possible, step up to speed up projects.👉 Feel free to contact us for the current delivery time or a quick quote https://flexxcon.com/offerte-aanvragen/

-

FlexxCon specialises in glass fibre reinforced plastic (GRP) products. We supply a complete range, varying from gratings, profiles and steps to complete constructions and customised solutions. In addition to delivery from stock, we also provide support with engineering, design and assembly, so that you can always count on a sustainable and safe customised solution.