Plastic grid

R2-MG1

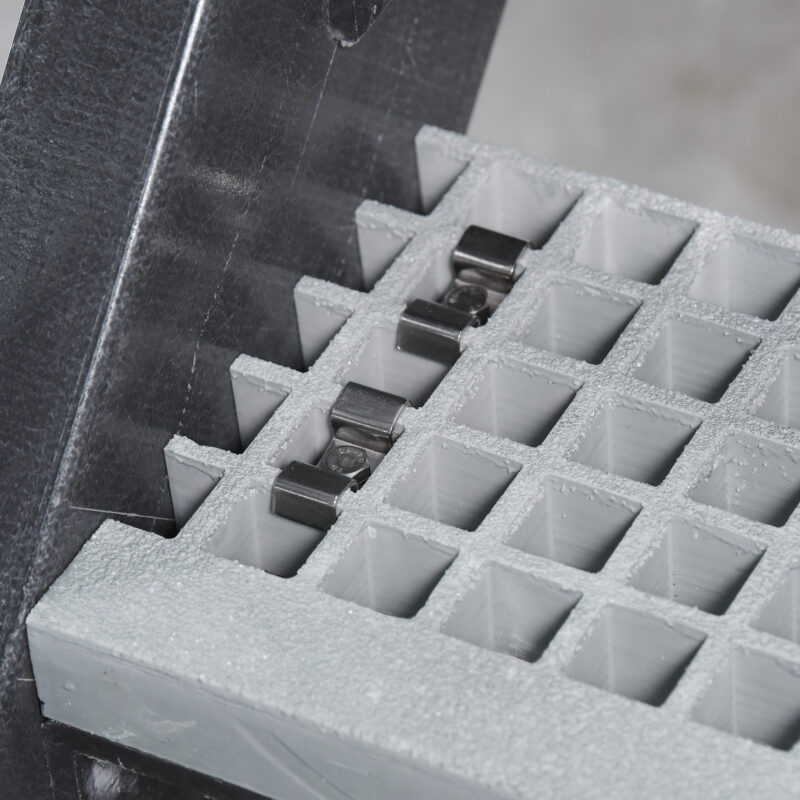

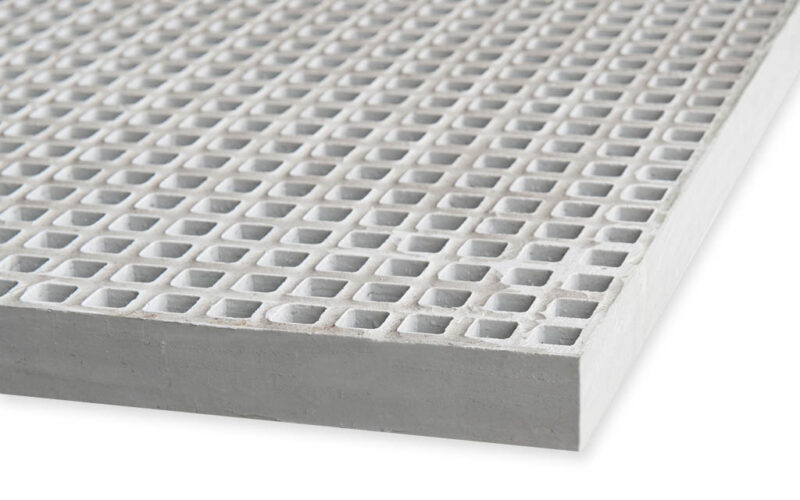

This GRP grating made of isophthalic polyester is suitable for various applications and available in multiple sizes. This type has a 19×19 mm mesh and is equipped with a meniscus anti-slip top layer.

- Mesh sizes

- 19 mm x 19 mm

- Heights

- 25mm

- Resin types

- Isophthalic polyester

- Toplayer

- Meniscus

- Colors

- Gray

- Weight types

- 12,2 kg/m²

Specifications & dimensions

| Article number | Height | Length | Width | Quotation |

|---|---|---|---|---|

| R2-2412-MG1 | 25 mm | 2445 mm | 1225 mm | Request a quotation |

| R2-CTS-MG1 | 25 mm | CUST | CUST | Request a quotation |

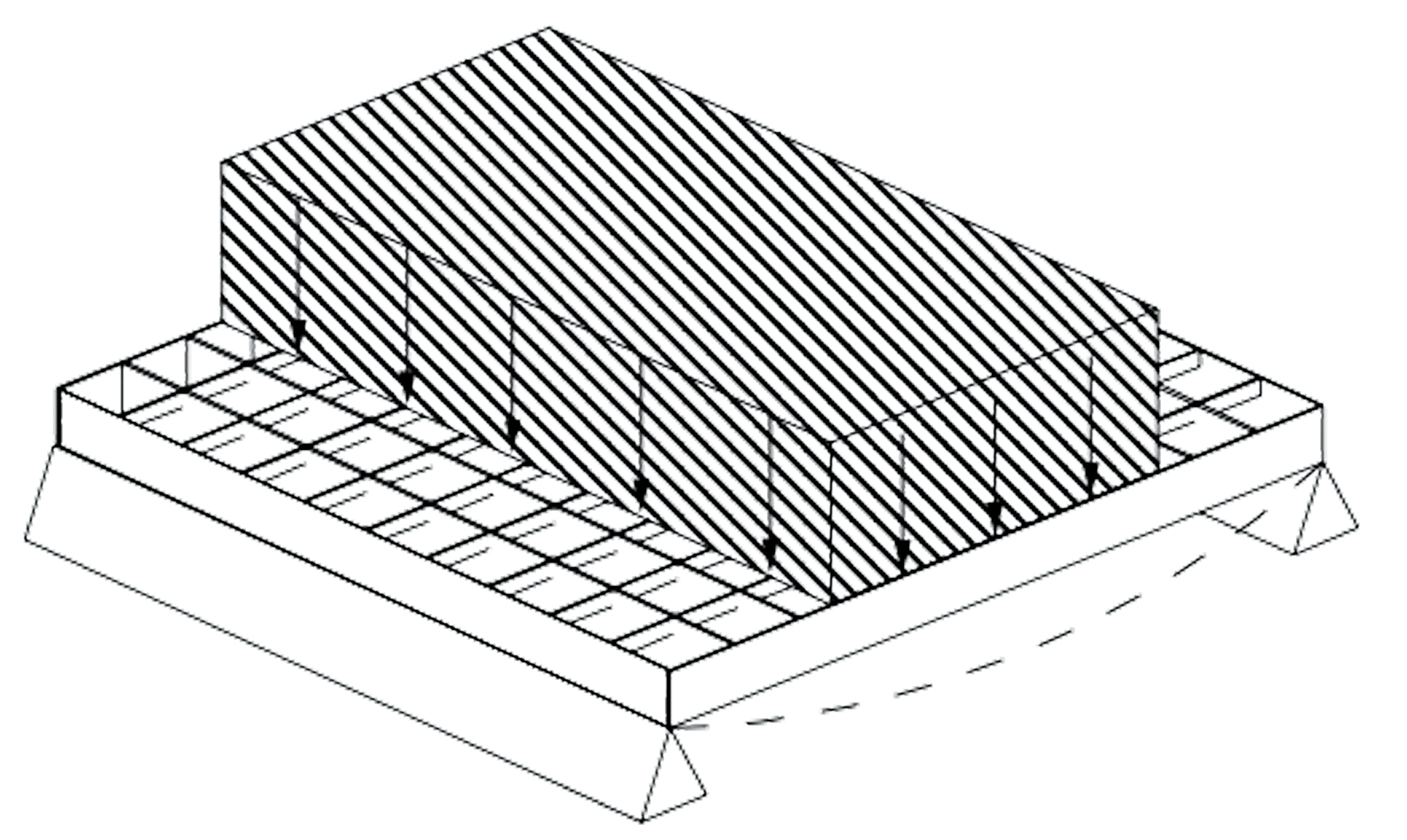

Strength table for uniform load

Grating height 25 millimetres Mazen 38 x 38 millimetres

| Clear span | Uniformly distributed load in kN/m² | Maximum recommended load in kN/m² | Ultimate load (kN/m²) | ||

|---|---|---|---|---|---|

| 2,5 | 5 | 10 | |||

| 400 | < 1 | <1 | <1 | 45 | 197 |

| 500 | < 1 | < 1 | 1 | 28 | 127 |

| 600 | 2 | 3 | 6 | 20 | 88 |

| 700 | 3 | 6 | 9 | 14 | 65 |

| 800 | 4 | - | - | 11 | 50 |

| 900 | 8 | - | - | 9 | 40 |

| 1000 | 12 | - | - | 7 | 32 |

| 1100 | - | - | - | 6 | 27 |

| Deflection in mm | |||||

Fire class: B(fl)-s1 according to DIN EN ISO 13501

Anti-slip classification: Class rating DIN 51130: R13

Frequently asked questions about this timetable

-

The correct grating height depends on the load, the free span and the application of the GRP grating. At FlexxCon, we work with various standard heights, each suitable for a specific use:

Height Typical application Characteristics 13 mm (R1) Screening or protective grating Intended for shielding machines or conveyor belts, etc., not suitable as a walkway grating. 25 mm (R2) Light loads, walkways, inspection floors Lightweight, easy to process, suitable for small spans. 30 mm (R3) General use, work floors, platforms Good balance between rigidity and weight. 38 mm (R4) Heavier loads, technical floors, industrial platforms Most commonly used version; suitable for heavier foot traffic and medium to larger spans. 50 mm (R5) Heavy industrial applications Very rigid version; suitable for large spans or high loads. How do you choose the right height?

The choice of the right grating height depends on:

- the free span (the greatest distance between two supports),

- the load occurring (e.g. standard live load: 2.5 kN/m² or a prescribed value),

- the permissible deflection (comfort and safety),

- and the available installation height.

We are happy to advise you on determining the right height for your situation.

👉 Contact us for a calculation or technical advice. -

The correct mesh size for your GRP grating depends on the application, the desired flow rate and the requirements in terms of safety, comfort and load. The mesh indicates the distance between the bearing bars (the centre-to-centre distance, or C.T.C.). The free opening is the actual space between the bearing bars.

At FlexxCon, we use the following standard mesh types:

Mesh type Mesh spacing (C.C.) Free opening Application/characteristics 19×19 mm 19 mm Approx. 13 mm Fine mesh grating, prevents small objects from falling through. Suitable for installation rooms, platform edges and safety zones. 38×38 mm 38 mm Approx. 31 mm Most commonly used mesh; good balance between strength, weight and permeability. Suitable for general industrial applications. 50×50 mm 50 mm Approx. 43 mm Coarser mesh, suitable for industrial applications. Used where there is no risk of small objects falling through. How do you choose the right mesh?

The choice of the right type of mesh depends on:

- the safety requirements (fall-through, chop-proof, contact with tools or liquids),

- the desired light and liquid permeability,

- and, if applicable, aesthetics or connection with other gratings.

During the design phase, we recommend also considering the position of open or closed meshes on the outer edge.

👉 Still can’t decide? We are happy to help you select the right mesh.

-

At FlexxCon, we use different grate types to clearly specify the properties of our GRP grates. Each grating type can be identified by a fixed item number structure. Do you already know one or more specifications? Then use the coding to determine the correct grating type. If you do not yet know the specifications or are unable to make a choice, we would be happy to refer you to our other FAQs about this specification or advise you personally!

An example: R4-MG3

Code Meaning Explanation R Type of item Indication of which product is involved:

R = Grate

T = Stair tread4 Height Indicates the grating height:

2 = 25 mm

3 = 30 mm

4 = 38 mm

5 = 50 mmM Top layer Surface type:

M = Meniscus (also called concave)

Q = Quartz grit (anti-slip grit layer)

S = Smooth (smooth surface)G Colour Colour coding:

G = Grey

E = Yellow

B = Blue

R = Green

C = Custom colour3 Mesh size Centre-to-centre distance of the support bars:

3 = 38×38 mm

1 = 19×19 mm

5 = 50×50 mm

2 = 25×25 mm

C= Closed top plate on 38 x 38 mm mesh, grating height + 3 mmAre you unable to decide or would you like advice on an application?

👉 Please feel free to contact us, we will be happy to help you choose the right GRP grating. -

At FlexxCon, we supply our GRP gratings with an isophthalic polyester fire retardant resin (ISOFR) as standard. This resin offers an excellent balance between mechanical strength, chemical resistance and fire retardant properties. Ideal for industrial applications.

We also supply vinyl ester (VE) and phenolic (PH) gratings as options, depending on the requirements of your project.

Resin type Designation Key properties Typical applications Isophthalic polyester (fire retardant) ISOFR Our standard resin with high chemical resistance, high strength and fire-retardant properties. Industrial environments, work floors, landings and platforms. Suitable for most general applications. Vinyl ester VE Very high chemical resistance, resistant to acids, alkalis and solvents. Also higher temperature resistance than ISOFR. Chemical industry, water treatment, maritime sector and environments with aggressive media. Phenolic PH Excellent fire resistance and low smoke emission. Resistant to high temperatures and complies with strict fire standards. Offshore, shipping, oil and gas industry, tunnels and transport applications. Orthophthalic polyester OP Basic type polyester resin with limited chemical and fire performance. Not suitable for heavy industrial or fire-sensitive applications. Not available as standard from FlexxCon. Why do we choose ISOFR as standard?

Many suppliers use orthophthalic polyester as their standard resin, but this often does not meet the requirements of industrial applications.

At FlexxCon, we therefore supply ISOFR gratings as standard, so you can be sure of a high-quality, high-performance grating.For projects with specific requirements, such as high chemical exposure, ATEX environments or strict fire standards, we recommend choosing vinyl ester or phenolic resin. We would be happy to advise you personally on this!

👉 Not sure which resin is best suited to your application? We are happy to help you choose the right material based on the environment, load and safety standards.

-

In GRP gratings, open and closed meshes refer to the finish of the outer edge of the grating.

A GRP grating consists of a fixed mesh pattern, for example meshes with a centre-to-centre distance of 38.1 mm and a bearing bar thickness of 7 mm.

Depending on where the grating is cut, the outer edge can:

- end on a bearing bar, which we call a closed mesh (the edge is closed), or

- end in the middle of a mesh, which we call an open mesh (the edge has an opening).

An open mesh is not a problem in terms of construction: the strength and load-bearing capacity remain the same. However, this may be undesirable from an aesthetic or safety point of view, for example at the outer edge of a platform or staircase. In such cases, the open side is often placed against a closed side of an adjacent grating, so that no open edge is visible or accessible.

When cutting GRP gratings to size, we cannot cut through a bearing bar. That is why we always cut between the bearing bars (in the mesh). If your dimensions are such that the cut falls within a bearing bar, the dimensions can be slightly rounded off to the nearest cutting point in the mesh pattern. This does not affect the quality, but it can determine whether a grating ends with an open or closed mesh.

💡 Design tip: During the design phase, it is advisable to adjust the dimensions to a closed mesh. This ensures a neat edge finish and prevents open meshes on visible or walkable edges. We have tables available to determine the optimal grating dimensions, which can be downloaded here.

-

Standard GRP gratings from stock can be shipped immediately and are often delivered within 1–2 working days.

Customised GRP gratings are cut from stock panels. The exact delivery time depends on the desired dimensions and the current cutting schedule.

It is best to discuss the shortest lead time with you personally.Due to their complexity, GRP structures (such as stairs, landings and platforms) usually have a longer lead time.

However, we are flexible in planning and production and can, where possible, step up to speed up projects.👉 Feel free to contact us for the current delivery time or a quick quote https://flexxcon.com/offerte-aanvragen/