Plastic grid

ZR4-MG5V

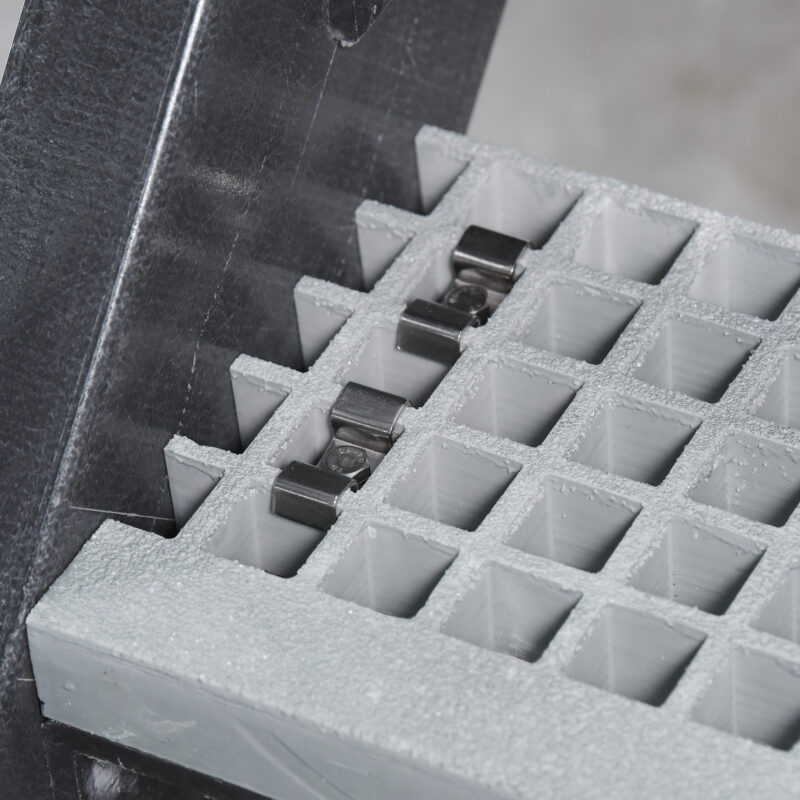

Our GRP heavy-duty gratings (high load capacity) are designed for high loads and intensive use. They are corrosion-resistant, low-maintenance and suitable for demanding industrial applications.

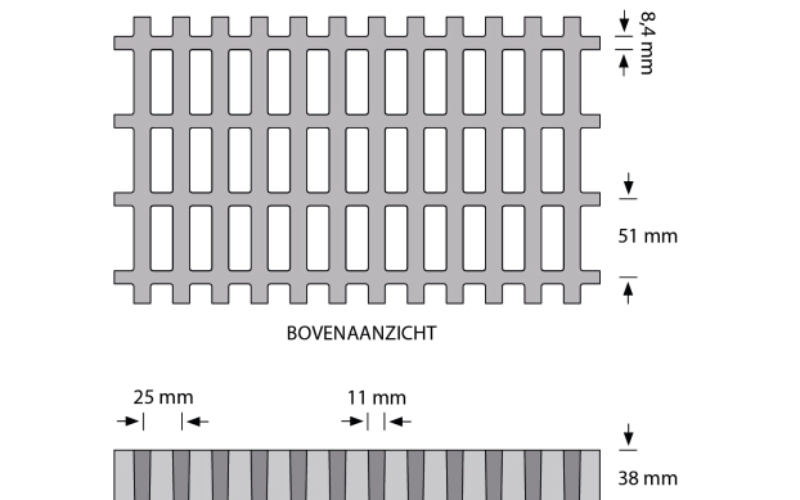

- Heights

- 38mm

- Resin types

- Vinylester

- Toplayer

- Meniscus

- Colors

- Black

- Mesh sizes

- 51 mm x 25 mm

| Article number | Height | Length | Width | Quotation |

|---|---|---|---|---|

| ZR4-3612-MG5V | 38 | 3660 | 1230 | Request a quotation |

| ZR4-CTS-MG5V | 38 | CUST | CUST | Request a quotation |

Frequently asked questions about this timetable

-

These HLC GRP gratings are designed for higher loads and larger spans than standard GRP gratings. They combine the well-known advantages of GRP (lightweight, corrosion-resistant and low-maintenance) with increased structural capacity.

HLC gratings are usually manufactured as moulded GRP gratings with:

- • higher loads to be absorbed,

- • greater grating height,

• heavier bar construction - • and/or a modified mesh structure.

⚙️ What makes HLC gratings different?

In HLC gratings, the construction (support bars) is optimised to:

• enable larger free spans,

• and limit deflection during intensive use.Like other moulded GRP gratings, HLC gratings bear loads in multiple directions.

With four-sided support, the shortest span can therefore often be used as the design span.Typical applications

GRP HLC gratings are used where standard gratings are not sufficient, for example in:

• industrial environments (often gutters) with heavier traffic,

• technical floors with point loads (machines, equipment),

• situations with large spans or limited support,🧩 Summary

HLC = High Load Capacity

Suitable for higher loads and larger spans

Lightweight, strong and corrosion-resistant alternative to steel👉 Would you like to know whether an HLC grating is required for your application, or whether a standard GRP grating is sufficient? We are happy to advise you based on load, span and use.

-

Traditional steel or stainless steel gratings consist of bearing bars and filler bars. The bearing bars determine the bearing direction: the grating bears in one main direction. Often referred to as:

With GRP gratings, this works differently, depending on the type of grating:

Moulded GRP gratings (the standard at FlexxCon): Our moulded GRP gratings are cast in one piece from fibreglass and resin. There are no separate bearing or filler bars; the grating forms a single cohesive structure in which all bars contribute to the strength.

This means:

- The grating bears load in four directions.

- There is no fixed bearing direction as with steel or stainless steel.

- With four-sided support, the shortest span can generally be used as the design span.

This multi-directional load-bearing capacity makes moulded GRP gratings strong, stable and flexible in application, even in complex support situations.

Pultruded GRP gratings (specific applications): In pultruded GRP gratings, the structure is made up of load-bearing and filler bars.

These behave in a similar way to steel gratings:- The load-bearing direction is parallel to the load-bearing bars.

- The strength is mainly directional, transferring to two sides.

- They are used where long spans or high stiffness in one direction are required.

👉 When designing or replacing gratings, it is important to know what type you have and how it is supported. We are happy to advise you on the right choice of grating, support and span.